Thermally-modified wood

Thermally-modified Spruce Tops for Plucked and String Instruments

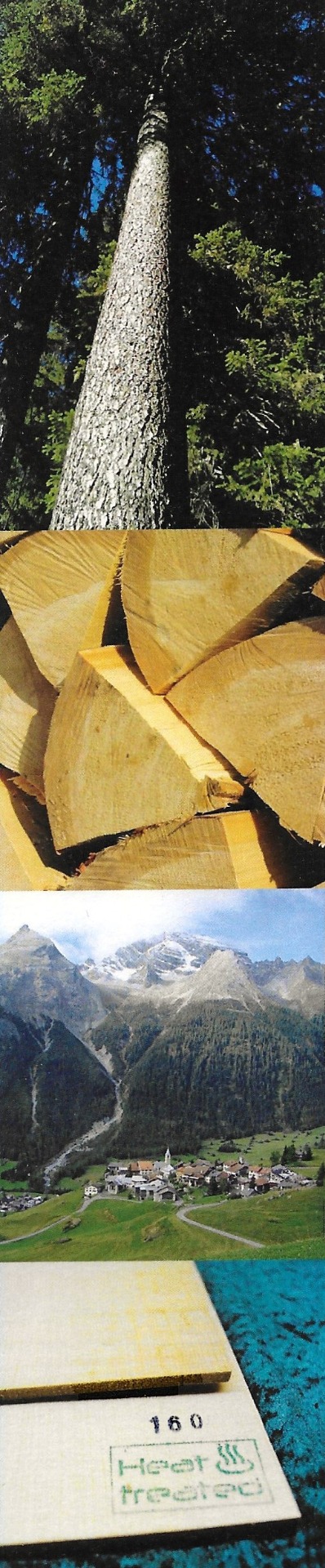

Swiss mountain spruce (picea abies) has proven itself trough the centuries on the strength of its tonal characteristics. Wood used in the making of musical instruments has to be light, grow slowly and yet at the same time exhibit a high degree of stiffness.We source spruce at altitudes between 1,300 and 2,000 meters. As a rule, we select trees with a diameter of at least 50 cm. A tree of this diameter will have reached its maximum age of at least 200 years.

We fell trees only in the winter and in the time before the new moon (moon wood). The logs are quartered by hand at our mill and processed further in our tonewood workshop. We take care to do all the steps ourselves. Only this way can we ensure the quality of our products - from the standing tree in the forest to the finished product.

Our thermally-treated tops are heated to a maximum temperature of 160°C in our own dedicated thermal oven. During the whole process they are under vacuum pressure. As a result of this process known as torrefaction, the wood is "caramelized" and takes on a darker color. The resin and by-products of the Hemicellulose and the lignin also partially volatilize. As a result, the tops are lighter in weight and after the torrefaction process, exhibit a higher degree of sound conduction. The wood's ability to take on and shed moisture is also strongly reduced.

Advantages of thermally-treated spruce compared untreated spruce:

- Higher speed of sound transference (radially and longitudinally)

- Lower density

- Can be used immediately without further aging

- Lower dimensional shrinkage and expansion of wood